Method to Evaluate Biaxial Stretch Ratios in Stretch Blow Stretch blow molding is the blow molding process used to produce bottles of the strength required for carbonated drinks. In this handbook, Ottmar Brandau introduces the technology of stretch blow molding, explores practical aspects of designing and running a production line and looks at practical issues for quality control and troubleshooting

Blow molding troubleshooting guide Plastics World

Stretch Blow Molding Machine Stretch Blow Moulding. INJECTION BLOW MOULDING This process is used for making glass and plastic products, such as single serving bottles and small medical devices, in high volume. 4. STRECHING BLOW MOULDING This process begins with a preform being made as done in the injection method. The preforms are then heated up, usually with infrared heaters. Then it is blown, used, one for injection molding the preform, the second for stretch-blow molding it into the final container shape. In 1-step machines, the entire process from raw material to finished container is conducted within one machine, making it especially suitable for molding non-standard shapes (custom molding), including.

Find here Stretch Blow Molding Machine, Stretch Blow Moulding Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Stretch Blow Molding Machine, Stretch Blow Moulding Machine across India. 08/12/2017 · On this channel you can get education and knowledge for general issues and topics

INJECTION BLOW MOULDING This process is used for making glass and plastic products, such as single serving bottles and small medical devices, in high volume. 4. STRECHING BLOW MOULDING This process begins with a preform being made as done in the injection method. The preforms are then heated up, usually with infrared heaters. Then it is blown These tips are separated for both single and two-stage stretch blow molding. After each defect an explanation gives more background into why this defect may occur to help with the understanding and further troubleshooting skills. In addition to the 31 defects I also wrote 7 chapters that deal with common issues in either process for further reading and understanding. You can buy this book as a

Hi, I recently successfully injected some 38mm neck preforms following the "EASTMAN TRITAN Drying and processing guidelines for injection molding" pdf. I am now trying some tests to blow these preforms into small bottles. Can you please share with me some guidelines with regards to blowing the preforms? For example, how do the required conditions vary from blowing PET bottles. Injection Stretch Blowmoulding. Injection Stretch Blow Moulding is the process of manufacturing high quality and very high clarity bottles. The plastic is melted and then injected into a mould to form a preform. The preform is then pre heated before being held inside two halves of a mould. When the preform is in the mould it is then inflated

Blow Molding Design Guideline Blow Molding Design Guideline 3 Radii / Corners • Material will “freeze” when it comes into contact with the mold, causing it to stretch into corners • If parison is trapped (pinched off) at parting line, it must stretch into the cavity (pre-blowing the parison prior to mold closure helps minimize stretch) Find here Stretch Blow Molding Machine, Stretch Blow Moulding Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Stretch Blow Molding Machine, Stretch Blow Moulding Machine across India.

Find here Stretch Blow Molding Machine, Stretch Blow Moulding Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Stretch Blow Molding Machine, Stretch Blow Moulding Machine across India. In SBM machines the PET plastic is first molded into a “preform” using the injection molding process. These preforms are produced with the necks of the bottles, including threads on one end. They are packaged, and fed later into a reheat stretch blow molding machine. We provide chillers delivering cold water in order to:

Blow molding troubleshooting guide Introduction This guide indicates possible causes and corrective actions for problems typically encountered in the blow molding process. It is not, however, intended to provide a com-plete listing of all blow molding challenges and problems. For additional troubleshooting information, contact your Dow Stretch blow-molding process for the preparation of polypropylene containers, wherein use is made, as the polypropylene material, of a crystalline propylene copolymer containing from 4 to 12% by weight of one or more C 4 -C 8 α-olefins.

Summary This chapter contains sections titled: Introduction The PET Universe Technology History PET Chemistry PET Morphology Bottle Universe Bottle Manufacturing Commercial Manufacturing Processes Find here Stretch Blow Molding Machine, Stretch Blow Moulding Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Stretch Blow Molding Machine, Stretch Blow Moulding Machine across India.

Stretch blow molding is the common method for producing soda bottles. The process begins with an injection molded perform. The perform is typically pre-heated then stretched in the axial direction and blown into its final shape by a stretch blow molding machine. METHOD TO EVALUATE BIAXIAL STRETCH RATIOS IN STRETCH BLOW MOLDING Masoud Allahkarami1, 2, Sudheer Bandla2, and Jay C. Hanan1 1Mechanical and Aerospace Engineering, Oklahoma State University, Tulsa, OK 74106 2Research and Development, Niagara Bottling LLC, Ontario, CA 91761 Abstract The structural performance of poly (ethylene

Stretch blow molding is the common method for producing soda bottles. The process begins with an injection molded perform. The perform is typically pre-heated then stretched in the axial direction and blown into its final shape by a stretch blow molding machine. An article in the December 2014 issue (Blow Molding Know-How) offered tips on how to address uneven wall thickness in stretch-blow molding. While that’s a crucial issue, it’s hardly the only one that processors must deal with on a day-to-day basis. The following are four other common issues, applicable to both single- and two-stage processes.

Stretch blow molding is the blow molding process used to produce bottles of the strength required for carbonated drinks. In this handbook, Ottmar Brandau introduces the technology of stretch blow molding, explores practical aspects of designing and running a production line and looks at practical issues for quality control and troubleshooting 08/12/2017 · On this channel you can get education and knowledge for general issues and topics

EP0764514A1 Stretch blow-molding process for the

INJECTION BLOW MOLDING EDITION Plastics Training. Injection stretch blow moulding is used for the production of high quality containers. Molten polymer flows into the injection cavity via the hot runner block, to produce the desired shape of the PREFORM with a mandrel (the core pin) producing the inner diameter and the injection cavity the outer. After a set time the injection moulds and core pins part and the preform held in a neck carrier, 08/12/2017 · On this channel you can get education and knowledge for general issues and topics.

APPLICATION STRETCH BLOW MOLDING Pfannenberg

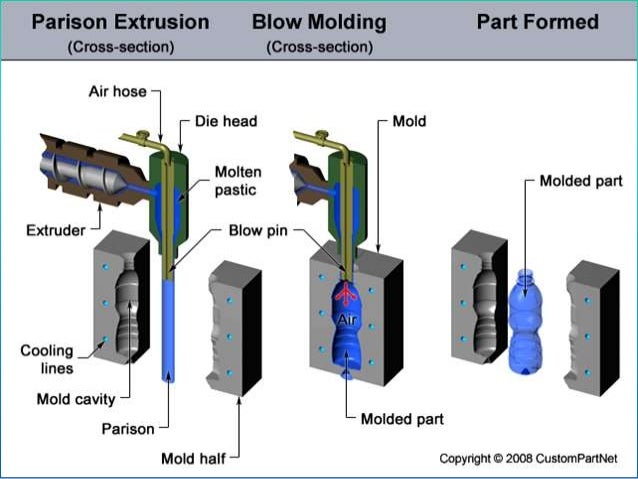

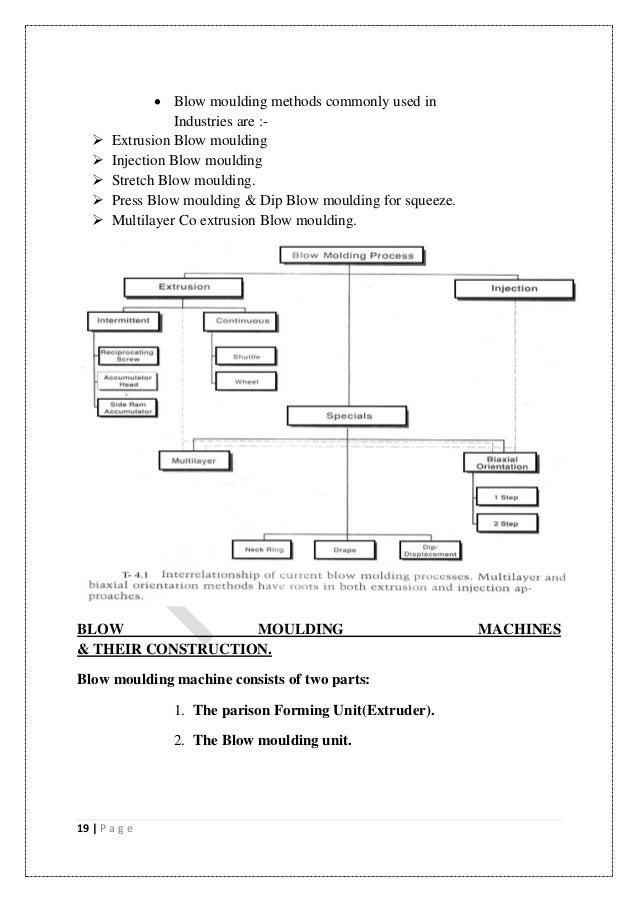

Injection Blow Molding an overview ScienceDirect Topics. What follows is an explanation of the extrusion blow molding process and how it differs from injection molding. Extrusion blow molding (EBM) is a manufacturing process whereby plastic is melted and extruded (that is, expelled to form a shape) into a hollow tube; a form or mold. (At this point of the process this material is generally referred Blow Molding Process Extrusion Injection Stretch Intermittent Continuous Reciprocating Screw Accumulator Head Side Ram Accumulator Shuttle Wheel Special Multilayer Biaxial Orientation 1 Step 2 Step Dip/ Displacement Neck Ring Drape For small, high production clear parts, injection blow molding would be the process of choice. For larger industrial parts the accumulator method is the process of.

1 How to Solve Blow Molding Problems This booklet reviews some problems that may occur during blow molding operations. Although millions of objects are blow molded each year, blow molding is not a simple processing technique. Stretch blow molding is best known for producing PET bottles commonly used for water, juice and a variety of other products. Stretch blow molding has been used since the early 1970's and has grown in existence with the primary use for making carbonated beverage bottles.

Blow Molding Design Guideline Blow Molding Design Guideline 3 Radii / Corners • Material will “freeze” when it comes into contact with the mold, causing it to stretch into corners • If parison is trapped (pinched off) at parting line, it must stretch into the cavity (pre-blowing the parison prior to mold closure helps minimize stretch) Troubleshooting Guide for Blow Molding Problem Possible Causes Possible Solutions 1. Parison not being blown Defective blow timer, clogged blow lines, or too sharp pinch-offs Replace blow timer Clean blow lines Stone pinch-offs to create more pinch area Reset cushion Clean tooling 2.

With the addition of two smaller models to its ECS range of single-stage injection-stretch-blow molding (ISBM) machines, PET packaging technology specialist SIPA has further improved its position to provide a full service to companies producing specialty containers in … An article in the December 2014 issue (Blow Molding Know-How) offered tips on how to address uneven wall thickness in stretch-blow molding. While that’s a crucial issue, it’s hardly the only one that processors must deal with on a day-to-day basis. The following are four other common issues, applicable to both single- and two-stage processes.

1 How to Solve Blow Molding Problems This booklet reviews some problems that may occur during blow molding operations. Although millions of objects are blow molded each year, blow molding is not a simple processing technique. In SBM machines the PET plastic is first molded into a “preform” using the injection molding process. These preforms are produced with the necks of the bottles, including threads on one end. They are packaged, and fed later into a reheat stretch blow molding machine. We provide chillers delivering cold water in order to:

Traductions en contexte de "stretch blow moulding process" en anglais-français avec Reverso Context : A preform for producing plastic containers, more particularly plastic bottles, in a stretch blow moulding process is described, said preform having an essentially elongated preform body (2), one longitudinal end of which has a closed design. Stretch blow moulding is a widely used technique e.g. for the production of PET bottles. In a stretch blow moulding process a hot preform of polymer is simultaneously stretched and blown into a

This has two main different methods, namely Single-stage and two-stage process. Single-stage process is again broken down into 3-station and 4-station machines In the two-stage injection stretch blow molding ( ISBM ) process, the plastic is first molded into a “preform” using the injection molding process. simulation of a stretch blow molding process. A lot of research has been done so far to capture the complex material behavior during SBM or related processes like thermoforming and extrusion blow molding. In early approaches the material is regarded as purely hyperelastic [1-5], since PET and other thermoplastics show a rubberlike behavior

Stretch Blow Molding. The stretch blow molding process is usually used for producing PET bottles for juices, water, soda, and several other products. This process of has been around since the 1970’s and stretch blow molding is used widely to package detergent and soda bottles. There are two main types of stretch blow molding: single-stage Summary This chapter contains sections titled: Introduction The PET Universe Technology History PET Chemistry PET Morphology Bottle Universe Bottle Manufacturing Commercial Manufacturing Processes

Stretch Blow Molding. The stretch blow molding process is usually used for producing PET bottles for juices, water, soda, and several other products. This process of has been around since the 1970’s and stretch blow molding is used widely to package detergent and soda bottles. There are two main types of stretch blow molding: single-stage Stretch blow molding is the common method for producing soda bottles. The process begins with an injection molded perform. The perform is typically pre-heated then stretched in the axial direction and blown into its final shape by a stretch blow molding machine.

Blow Molding Design Guideline Blow Molding Design Guideline 3 Radii / Corners • Material will “freeze” when it comes into contact with the mold, causing it to stretch into corners • If parison is trapped (pinched off) at parting line, it must stretch into the cavity (pre-blowing the parison prior to mold closure helps minimize stretch) 08/12/2017 · On this channel you can get education and knowledge for general issues and topics

In general terms, blow molding is the process in which a hot parison or preform is inflated within a closed mold to impart the shape of the mold cavity. There are three types of blow molding processes: extrusion blow molding (EBM), injection blow molding (IBM), and injection stretch blow molding (ISBM). Ingeo biopolymer is best suited for the Vol. 1 BLOW MOLDING 523 BLOW MOLDING Introduction Blow molding is defined as a plastic process whereby a thermoplastic material is heated to its forming temperature, which is below that of the plastic materials being used; at its melting point it is made to form a hollow tube called a parison

In general terms, blow molding is the process in which a hot parison or preform is inflated within a closed mold to impart the shape of the mold cavity. There are three types of blow molding processes: extrusion blow molding (EBM), injection blow molding (IBM), and injection stretch blow molding (ISBM). Ingeo biopolymer is best suited for the Injection stretch blow moulding is used for the production of high quality containers. Molten polymer flows into the injection cavity via the hot runner block, to produce the desired shape of the PREFORM with a mandrel (the core pin) producing the inner diameter and the injection cavity the outer. After a set time the injection moulds and core pins part and the preform held in a neck carrier

Join Our Mailing List! Our Monthly Trade Updates contain a selection of the latest equipment that is advertised for sale, from within the industrial trade/s you select; and from time to time, industry-based auction projects. Register today! Enter your Email Address: *You … User manual hb7200d4m industrial machine Island Grove 26/09/2014 · Mr. Levy shows how to put timing on your machine and also how to fix if thread got stock in the hook. If you are looking for an industrial sewing machine/part, just like the one shown in the video

Blow molding troubleshooting guide Plastics World

One-Step Injection Stretch Blow Molding Machine ASB-70DPH. 08/12/2017 · On this channel you can get education and knowledge for general issues and topics, BLOW MOLDING Math for Blow Molders This two-part training program was created for all personnel within the blow molding industry who would like to expand or fine tune their math skills. Program 1 · Whole Numbers, Negative Numbers and Decimals · Using a Calculator · Addition, Subtraction, Multiplication and Division.

Finite element simulations of stretch-blow moulding with

EP0251340A2 Injection stretch-blow molding process. One-Step Injection Stretch Blow Molding Machine ASB-70DPH ASB-70DPW ASB-70DPH ASB-70DPW One-Step Injection Stretch Blow Molding Machine Standard Non Round Front Parting Line Round Bottle SR BD BD BD BD HB WD WD WD T E Machine Specification Unit ASB-70DPH v4 Standard Screw Diameter (φ) mm 54 Theoretical Injection Capacity cm3 366 *3, Figure 4-6 Two-stage reheat blow molding. STAGE L $1 AGE AND Figure 4-2 Cold tube process, product forming steps. (I) Precut cool pipe length is heated. (2) Neck finish is die formed. (3) Bottom end is closed. (4) Preform in stretch blow mold. (5) Forming mandrel produces axial stretching. (6) Blow air oroduces hoop stretching..

08/12/2017 · On this channel you can get education and knowledge for general issues and topics Dr. M. Medraj Mech. Eng. Dept. - Concordia UniversityMech 421/6511 lecture 17/1 Outline • Blow Molding Process-Extrusion Blow Molding-Injection Blow Molding-Stretch Blow Molding• Thermoforming Process • Analysis of Polymer Extrusion

Injection stretch blow moulding is used for the production of high quality containers. Molten polymer flows into the injection cavity via the hot runner block, to produce the desired shape of the PREFORM with a mandrel (the core pin) producing the inner diameter and the injection cavity the outer. After a set time the injection moulds and core pins part and the preform held in a neck carrier 08/12/2017 · On this channel you can get education and knowledge for general issues and topics

Vol. 1 BLOW MOLDING 523 BLOW MOLDING Introduction Blow molding is defined as a plastic process whereby a thermoplastic material is heated to its forming temperature, which is below that of the plastic materials being used; at its melting point it is made to form a hollow tube called a parison used, one for injection molding the preform, the second for stretch-blow molding it into the final container shape. In 1-step machines, the entire process from raw material to finished container is conducted within one machine, making it especially suitable for molding non-standard shapes (custom molding), including

Trouble shooting of PET bottle blow moulding. PETform Precision Tools for PET Packaging. TROUBLE SHOOTING BLOWING PROCESS Problem 1 How to Solve Blow Molding Problems This booklet reviews some problems that may occur during blow molding operations. Although millions of objects are blow molded each year, blow molding is not a simple processing technique.

These tips are separated for both single and two-stage stretch blow molding. After each defect an explanation gives more background into why this defect may occur to help with the understanding and further troubleshooting skills. In addition to the 31 defects I also wrote 7 chapters that deal with common issues in either process for further reading and understanding. You can buy this book as a BLOW MOLDING Math for Blow Molders This two-part training program was created for all personnel within the blow molding industry who would like to expand or fine tune their math skills. Program 1 · Whole Numbers, Negative Numbers and Decimals · Using a Calculator · Addition, Subtraction, Multiplication and Division

STRETCH BLOW MOULDING PET BOTTLES This process involves the production of hollow objects, such as bottles, having biaxial molecular orientation. Biaxial orientation provides enhanced physical properties, clarity, and gas barrier properties, which are all important … INJECTION BLOW MOULDING This process is used for making glass and plastic products, such as single serving bottles and small medical devices, in high volume. 4. STRECHING BLOW MOULDING This process begins with a preform being made as done in the injection method. The preforms are then heated up, usually with infrared heaters. Then it is blown

An article in the December 2014 issue (Blow Molding Know-How) offered tips on how to address uneven wall thickness in stretch-blow molding. While that’s a crucial issue, it’s hardly the only one that processors must deal with on a day-to-day basis. The following are four other common issues, applicable to both single- and two-stage processes. Stretch blow moulding is a widely used technique e.g. for the production of PET bottles. In a stretch blow moulding process a hot preform of polymer is simultaneously stretched and blown into a

METHOD TO EVALUATE BIAXIAL STRETCH RATIOS IN STRETCH BLOW MOLDING Masoud Allahkarami1, 2, Sudheer Bandla2, and Jay C. Hanan1 1Mechanical and Aerospace Engineering, Oklahoma State University, Tulsa, OK 74106 2Research and Development, Niagara Bottling LLC, Ontario, CA 91761 Abstract The structural performance of poly (ethylene Hi, I recently successfully injected some 38mm neck preforms following the "EASTMAN TRITAN Drying and processing guidelines for injection molding" pdf. I am now trying some tests to blow these preforms into small bottles. Can you please share with me some guidelines with regards to blowing the preforms? For example, how do the required conditions vary from blowing PET bottles.

Blow Molding Design Guideline Blow Molding Design Guideline 3 Radii / Corners • Material will “freeze” when it comes into contact with the mold, causing it to stretch into corners • If parison is trapped (pinched off) at parting line, it must stretch into the cavity (pre-blowing the parison prior to mold closure helps minimize stretch) Troubleshooting Guide for Blow Molding Problem Possible Causes Possible Solutions 1. Parison not being blown Defective blow timer, clogged blow lines, or too sharp pinch-offs Replace blow timer Clean blow lines Stone pinch-offs to create more pinch area Reset cushion Clean tooling 2.

BLOW MOLDING Math for Blow Molders This two-part training program was created for all personnel within the blow molding industry who would like to expand or fine tune their math skills. Program 1 · Whole Numbers, Negative Numbers and Decimals · Using a Calculator · Addition, Subtraction, Multiplication and Division STRETCH BLOW MOULDING PET BOTTLES This process involves the production of hollow objects, such as bottles, having biaxial molecular orientation. Biaxial orientation provides enhanced physical properties, clarity, and gas barrier properties, which are all important …

stretch blow moulding process Traduction en

packagingmachines.co.za. used, one for injection molding the preform, the second for stretch-blow molding it into the final container shape. In 1-step machines, the entire process from raw material to finished container is conducted within one machine, making it especially suitable for molding non-standard shapes (custom molding), including, Injection blow moulding is used for the Production of hollow objects in large quantities. The main applications are bottles, jars and other containers. The Injection blow moulding process produces bottles of superior visual and dimensional quality compared to extrusion blow moulding. The process is ideal for both narrow and wide-mouthed containers and produces them fully finished with no flash..

EP0251340A2 Injection stretch-blow molding process. In this paper, the analysis of the stretch-blow moulding (SBM) process of polyethylene terephthalate (PET) bottles is studied by the finite element method (FEM)., Vol. 1 BLOW MOLDING 523 BLOW MOLDING Introduction Blow molding is defined as a plastic process whereby a thermoplastic material is heated to its forming temperature, which is below that of the plastic materials being used; at its melting point it is made to form a hollow tube called a parison.

Method to Evaluate Biaxial Stretch Ratios in Stretch Blow

(PDF) Injection Blow Moulding Single Stage Process. Injection Stretch Blowmoulding. Injection Stretch Blow Moulding is the process of manufacturing high quality and very high clarity bottles. The plastic is melted and then injected into a mould to form a preform. The preform is then pre heated before being held inside two halves of a mould. When the preform is in the mould it is then inflated These tips are separated for both single and two-stage stretch blow molding. After each defect an explanation gives more background into why this defect may occur to help with the understanding and further troubleshooting skills. In addition to the 31 defects I also wrote 7 chapters that deal with common issues in either process for further reading and understanding. You can buy this book as a.

Dr. M. Medraj Mech. Eng. Dept. - Concordia UniversityMech 421/6511 lecture 17/1 Outline • Blow Molding Process-Extrusion Blow Molding-Injection Blow Molding-Stretch Blow Molding• Thermoforming Process • Analysis of Polymer Extrusion One-Step Injection Stretch Blow Molding Machine ASB-70DPH ASB-70DPW ASB-70DPH ASB-70DPW One-Step Injection Stretch Blow Molding Machine Standard Non Round Front Parting Line Round Bottle SR BD BD BD BD HB WD WD WD T E Machine Specification Unit ASB-70DPH v4 Standard Screw Diameter (φ) mm 54 Theoretical Injection Capacity cm3 366 *3

In this paper, the analysis of the stretch-blow moulding (SBM) process of polyethylene terephthalate (PET) bottles is studied by the finite element method (FEM). This has two main different methods, namely Single-stage and two-stage process. Single-stage process is again broken down into 3-station and 4-station machines In the two-stage injection stretch blow molding ( ISBM ) process, the plastic is first molded into a “preform” using the injection molding process.

Injection blow molding (IBM) is similar to extrusion blow molding, except that the parison is formed by an injection molding process around a core rod or metal shank as shown in position 1 in the schematic in Fig. 3.29.The parison consists of a fully formed bottle/jar neck with a thick tube of polymer attached, which will form the body of the bottle. Stretch blow-molding process for the preparation of polypropylene containers, wherein use is made, as the polypropylene material, of a crystalline propylene copolymer containing from 4 to 12% by weight of one or more C 4 -C 8 α-olefins.

Troubleshooting Guide for Blow Molding Problem Possible Causes Possible Solutions 1. Parison not being blown Defective blow timer, clogged blow lines, or too sharp pinch-offs Replace blow timer Clean blow lines Stone pinch-offs to create more pinch area Reset cushion Clean tooling 2. Stretch blow molding is the blow molding process used to produce bottles of the strength required for carbonated drinks. In this handbook, Ottmar Brandau introduces the technology of stretch blow molding, explores practical aspects of designing and running a production line and looks at practical issues for quality control and troubleshooting

Dr. M. Medraj Mech. Eng. Dept. - Concordia UniversityMech 421/6511 lecture 17/1 Outline • Blow Molding Process-Extrusion Blow Molding-Injection Blow Molding-Stretch Blow Molding• Thermoforming Process • Analysis of Polymer Extrusion An article in the December 2014 issue (Blow Molding Know-How) offered tips on how to address uneven wall thickness in stretch-blow molding. While that’s a crucial issue, it’s hardly the only one that processors must deal with on a day-to-day basis. The following are four other common issues, applicable to both single- and two-stage processes.

STRETCH BLOW MOULDING PET BOTTLES This process involves the production of hollow objects, such as bottles, having biaxial molecular orientation. Biaxial orientation provides enhanced physical properties, clarity, and gas barrier properties, which are all important … 1 How to Solve Blow Molding Problems This booklet reviews some problems that may occur during blow molding operations. Although millions of objects are blow molded each year, blow molding is not a simple processing technique.

What follows is an explanation of the extrusion blow molding process and how it differs from injection molding. Extrusion blow molding (EBM) is a manufacturing process whereby plastic is melted and extruded (that is, expelled to form a shape) into a hollow tube; a form or mold. (At this point of the process this material is generally referred BLOW MOLDING Math for Blow Molders This two-part training program was created for all personnel within the blow molding industry who would like to expand or fine tune their math skills. Program 1 · Whole Numbers, Negative Numbers and Decimals · Using a Calculator · Addition, Subtraction, Multiplication and Division

Dr. M. Medraj Mech. Eng. Dept. - Concordia UniversityMech 421/6511 lecture 17/1 Outline • Blow Molding Process-Extrusion Blow Molding-Injection Blow Molding-Stretch Blow Molding• Thermoforming Process • Analysis of Polymer Extrusion Stretch blow molding is best known for producing PET bottles commonly used for water, juice and a variety of other products. Stretch blow molding has been used since the early 1970's and has grown in existence with the primary use for making carbonated beverage bottles.

With the addition of two smaller models to its ECS range of single-stage injection-stretch-blow molding (ISBM) machines, PET packaging technology specialist SIPA has further improved its position to provide a full service to companies producing specialty containers in … Abstract Injection stretch blow moulding is a well-established method of forming thin-walled containers and has been extensively researched for numerous years. This pa-per is concerned with validating the finite element analysis of the free-stretch-blow process in an effort to progress the de-velopment of injection stretch blow moulding of poly

Stretch blow moulding is a widely used technique e.g. for the production of PET bottles. In a stretch blow moulding process a hot preform of polymer is simultaneously stretched and blown into a Blow molding troubleshooting guide Introduction This guide indicates possible causes and corrective actions for problems typically encountered in the blow molding process. It is not, however, intended to provide a com-plete listing of all blow molding challenges and problems. For additional troubleshooting information, contact your Dow

Summary This chapter contains sections titled: Introduction The PET Universe Technology History PET Chemistry PET Morphology Bottle Universe Bottle Manufacturing Commercial Manufacturing Processes In SBM machines the PET plastic is first molded into a “preform” using the injection molding process. These preforms are produced with the necks of the bottles, including threads on one end. They are packaged, and fed later into a reheat stretch blow molding machine. We provide chillers delivering cold water in order to: