The A10V parts PDF serves as a comprehensive guide for understanding and maintaining Bosch Rexroth’s axial piston pumps, offering detailed insights into their design, functionality, and repair processes.

1.1 Overview of A10V Series

The A10V series, developed by Bosch Rexroth, represents a line of axial piston pumps designed for hydrostatic transmissions in open-loop circuits. These pumps are renowned for their variable displacement capability, allowing precise control over fluid flow by adjusting the swashplate angle. The series includes models such as A10VO, A10VSO, and A10VNO, each tailored for specific applications. With frame sizes ranging from 18 to 140, the A10V series offers versatility for both industrial and mobile hydraulic systems. Key features include proportional flow control, durability, and high efficiency. The pumps are widely used in machinery requiring smooth and adaptable hydraulic power. Their robust design ensures long service life, making them a reliable choice for demanding environments. The A10V series is supported by extensive documentation, including parts catalogs, ensuring easy maintenance and repair.

1.2 Importance of Parts PDF

The A10V parts PDF is an essential resource for technicians, engineers, and users of Bosch Rexroth hydraulic systems. It provides a detailed breakdown of all components, including pistons, barrels, port plates, and rotary groups, ensuring accurate identification and ordering of spare parts. This documentation is critical for maintaining and repairing A10V pumps, as it includes exploded diagrams, part numbers, and descriptions. By referring to the PDF, users can quickly locate and replace worn or damaged components, minimizing downtime and ensuring optimal system performance. Additionally, the PDF serves as a guide for troubleshooting common issues and verifying compatibility with remanufactured or new parts. Its comprehensive nature makes it indispensable for anyone working with A10V series pumps, helping to streamline maintenance and repair processes while adhering to OEM specifications.

1.3 Benefits of Using A10V Parts

Using genuine or high-quality A10V parts ensures optimal performance, reliability, and longevity of hydraulic systems. These components are designed to meet rigorous OEM standards, guaranteeing precision and durability. The axial piston design and swashplate technology enable efficient variable displacement, allowing for smooth flow control and adaptability in various applications. A10V parts are compatible with a wide range of models, including A10VO, A10VSO, and A10VNO series, making them versatile for industrial and mobile hydraulic systems. Additionally, remanufactured A10V parts offer a cost-effective alternative without compromising quality, while new parts provide unparalleled performance. The availability of detailed parts lists and diagrams in the A10V PDF ensures easy identification and procurement of components, minimizing downtime and ensuring seamless system operation. Overall, A10V parts are essential for maintaining peak efficiency and extending the lifespan of hydraulic equipment.

Key Features and Benefits

The A10V series offers axial piston design, variable displacement, and swashplate technology, ensuring efficient flow control, adaptability, and reliability in various industrial and mobile hydraulic applications.

2.1 Axial Piston Design

The A10V series features an advanced axial piston design, which ensures high efficiency and precise control in hydraulic systems. This design enables the pump to operate smoothly in open-loop circuits, making it ideal for industrial and mobile applications. The axial piston configuration allows for variable displacement, where the flow rate can be adjusted by changing the swashplate angle. This flexibility ensures optimal performance under varying operational demands. The design also incorporates a robust rotary group, including pistons, barrels, and retaining balls, which are crucial for the pump’s durability and reliability. The axial piston design minimizes wear and tear, reducing the need for frequent maintenance. Additionally, the availability of detailed parts lists in the A10V parts PDF simplifies the process of identifying and sourcing components, ensuring that repairs and replacements can be carried out efficiently.

2.2 Variable Displacement

Variable displacement is a key feature of the A10V series, enabling precise control over fluid flow in hydraulic systems. This functionality allows the pump to adjust its output based on operational demands, ensuring efficient performance. The displacement is regulated by the swashplate angle, which can be modified to vary the flow rate smoothly. This adaptability makes the A10V series ideal for applications requiring flexible hydraulic control. The variable displacement design enhances system efficiency by delivering only the required amount of fluid, reducing energy consumption and heat generation. It also allows for seamless integration into open-loop circuits, where consistent flow regulation is critical. The A10V parts PDF provides detailed insights into the components and mechanisms that enable variable displacement, facilitating maintenance and repairs. This feature is a cornerstone of the A10V series, offering unparalleled versatility in industrial and mobile hydraulic systems.

2.3 Swashplate Technology

The A10V series utilizes advanced swashplate technology to achieve precise control over fluid flow and pressure in hydraulic systems. The swashplate, a critical component, allows for smooth adjustment of the pump’s displacement by altering its angular position. This design ensures efficient performance across varying operational conditions. Swashplate technology enables the pump to operate in open-loop circuits, providing consistent and reliable flow regulation. It also facilitates seamless integration into industrial and mobile applications, where adaptability and precision are essential. The A10V parts PDF details the construction and functionality of the swashplate, highlighting its role in optimizing system efficiency. By enabling variable displacement, the swashplate contributes to reduced energy consumption and enhanced overall system performance. This technology is a key innovation in the A10V series, making it a preferred choice for demanding hydraulic applications.

Types of A10V Pumps

The A10V series includes A10VO, A10VSO, and A10VNO models, each designed for specific hydraulic applications, offering variable displacement and advanced control systems for optimal performance.

3.1 A10VO Series

The A10VO series is a variant of the A10V axial piston pumps, designed for hydrostatic transmissions in open-loop circuits. These pumps feature a swashplate design, allowing for smooth and precise adjustment of flow rates. The A10VO series is known for its variable displacement capability, making it suitable for applications where flow needs to be proportional to drive speed. Available in various frame sizes, including 18, 28, 45, 71, 100, and 140, these pumps are widely used in industrial and mobile machinery. The series supports multiple control options, such as electro-proportional and mechanical controls, ensuring flexibility for diverse operational requirements. A10VO pumps are also compatible with remanufactured parts, offering a cost-effective solution for maintenance and repair. The A10V parts PDF provides detailed breakdowns of components like pistons, barrels, and rotary groups, essential for efficient servicing and replacement.

3.2 A10VSO Series

The A10VSO series represents a high-performance line of axial piston pumps designed for hydrostatic transmissions in open-loop systems. These pumps are characterized by their swashplate design, enabling smooth flow adjustment proportional to drive speed and displacement. The A10VSO series is available in various frame sizes, including 18, 28, 45, 71, 100, and 140, catering to both industrial and mobile applications. They support multiple control options such as DR, DFR, and DFR1, providing flexibility for different operational needs. The A10VSO pumps are known for their reliability and durability, making them a preferred choice for demanding hydraulic systems. The A10V parts PDF offers a detailed breakdown of components, including pistons, barrels, and rotary groups, facilitating efficient maintenance and repair. Remanufactured parts are also available, offering a cost-effective solution while maintaining OEM specifications and performance standards. This series is widely recognized for its versatility and robust design.

3.3 A10VNO Series

The A10VNO series is a specialized line of axial piston pumps designed for specific applications within the A10V family. Unlike the variable displacement models, the A10VNO series typically features a fixed displacement design, making it suitable for closed-loop hydraulic systems where precise flow control is not required. These pumps are often used in industrial settings where consistent performance is critical. The A10VNO series is known for its robust construction and reliability, ensuring long service life even in demanding environments. The A10V parts PDF provides a detailed breakdown of components, including pistons, barrels, and port plates, essential for maintenance and repair. Remanufactured parts are also available, offering a cost-effective alternative to new components while maintaining OEM specifications. This series is a reliable choice for applications requiring fixed displacement hydraulic solutions.

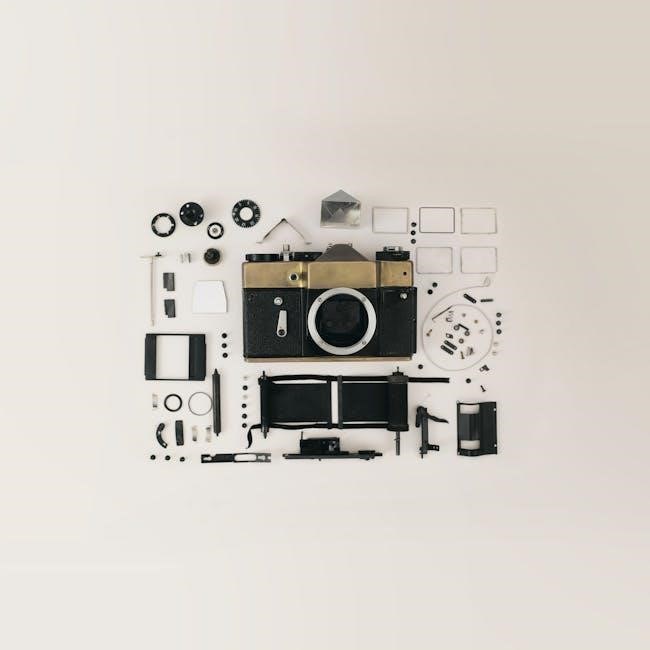

Parts Breakdown

The A10V parts PDF provides a detailed breakdown of components, including pistons, barrels, port plates, and rotary groups, each with item numbers, descriptions, and quantities for easy identification and ordering;

4.1 Pistons and Components

Pistons are critical components in A10V pumps, designed to withstand high pressure and wear. They are typically constructed from durable materials and are precisely engineered for smooth operation. The PDF includes detailed specifications, part numbers, and diagrams for pistons, ensuring accurate identification and replacement. Each piston is paired with components like piston shoes, retainers, and springs, which are essential for maintaining proper alignment and sealing within the barrel. The document also outlines the quantity and compatibility of these parts across various A10V models, making it easier for users to source the correct components. Proper maintenance and timely replacement of these elements are vital to ensure optimal pump performance and longevity.

4.2 Barrels and Port Plates

The barrel and port plates are integral to the A10V pump’s operation, ensuring proper fluid flow and pressure distribution. The barrel houses the pistons and is constructed from high-strength materials to withstand the rigors of hydrostatic applications. Port plates are responsible for directing fluid flow as the pump operates, with their precise machining ensuring minimal leakage and optimal efficiency. The A10V parts PDF provides detailed part numbers, dimensional specifications, and compatibility information for barrels and port plates across various pump models. This enables users to identify and order the correct components efficiently. The document also highlights the importance of proper installation and alignment to maintain the pump’s performance and longevity. Regular inspection and replacement of these parts are crucial to preventing downtime and ensuring reliable operation in demanding industrial and mobile applications.

4.3 Rotary Groups and Retaining Balls

The rotary group is a critical component of the A10V pump, comprising the shaft, bearings, and other moving parts that enable the pump’s axial piston design to function efficiently. Retaining balls play a vital role in securing these components in place, ensuring smooth operation and preventing wear. The A10V parts PDF provides detailed specifications for rotary groups and retaining balls, including part numbers, material grades, and installation guidelines. Proper maintenance of these parts is essential to avoid premature wear and ensure optimal performance. The PDF also outlines compatibility across different A10V models, making it easier to source the correct replacement parts. Regular inspection and timely replacement of worn or damaged components are crucial to maintaining the pump’s reliability and extending its service life in demanding industrial and mobile applications.

Ordering and Sourcing

Accurate ordering requires model codes and serial numbers to ensure compatibility. Authorized dealers offer genuine parts, while remanufactured options provide cost-effective solutions with OEM specifications and quick shipment options available.

5.1 Essential Information for Ordering

When ordering parts for the A10V series, it is crucial to provide specific details to ensure compatibility and accuracy. The model code, such as (A)A10V(S)O28, and the serial number are essential for identifying the correct components. Additionally, specifying the frame size (e.g., 18, 28, 45, 71, 100, 140) and control type (e.g., DR, DFR, DFLR) helps in selecting the right parts. Including the pressure rating (e.g., 4000 PSI) and any optional features (e.g., shaft options) ensures the parts meet the system’s requirements. Referencing the parts list from the A10V parts PDF guarantees accurate ordering. Providing this information helps suppliers deliver the correct components, reducing delays and ensuring proper functionality. Always verify the details with authorized dealers to avoid errors and receive genuine or remanufactured parts that meet OEM specifications.

5.2 Authorized Dealers and Suppliers

Obtaining A10V parts from authorized dealers ensures authenticity and compliance with Bosch Rexroth’s quality standards. Companies like FluiDyneFP and Bosch Rexroth distributors specialize in providing genuine or remanufactured components. These suppliers offer expertise in identifying the correct parts based on model codes and serial numbers. Purchasing from authorized sources guarantees adherence to OEM specifications, ensuring optimal performance and longevity. Additionally, authorized dealers provide detailed documentation, such as parts lists and diagrams, to facilitate accurate ordering. They often offer quick shipment options and technical support, making them a reliable choice for both new and remanufactured parts. Always verify the supplier’s authorization status to avoid counterfeit or incompatible components. Using authorized dealers minimizes risks and ensures that the A10V parts meet the required operational standards, supporting the overall efficiency and reliability of hydraulic systems.

5.3 Remanufactured vs. New Parts

When sourcing A10V parts, choosing between remanufactured and new components is crucial. Remanufactured parts are restored to meet OEM specifications, offering a cost-effective alternative without compromising performance. They undergo rigorous testing to ensure reliability and longevity, making them a viable option for budget-conscious buyers. New parts, on the other hand, are built from scratch with original materials, providing maximum durability and typically coming with a manufacturer’s warranty. Both options are supported by authorized dealers, but remanufactured parts are often preferred for their lower cost and faster availability. However, for critical applications requiring zero wear, new parts are recommended. Always verify the source and certifications to ensure quality, whether opting for remanufactured or new components. This choice depends on specific needs, budget constraints, and the desired level of performance and assurance.

Maintenance and Repair

Regular maintenance ensures optimal performance and extends the lifespan of A10V pumps. Routine inspections, seal replacements, and bearing lubrication are essential. Repair procedures often involve disassembling, inspecting, and replacing worn components. Troubleshooting common issues like leakage or noise helps prevent major breakdowns. Always follow OEM guidelines for reliable outcomes.

6.1 Routine Maintenance

Regular maintenance is crucial for ensuring the optimal performance and longevity of A10V hydraulic pumps. Start by inspecting seals and gaskets for signs of wear or leakage, as these are common failure points. Next, check the filter for contamination and replace it if necessary to prevent debris from damaging internal components. Pressure testing is another essential step to verify that the pump operates within the specified pressure range. Additionally, lubricate moving parts and bearings according to the manufacturer’s recommendations to reduce friction and wear. Visual inspections of the rotary group, pistons, and port plates can help identify potential issues early. Finally, ensure all bolts and connections are tightened to the correct torque specifications. By following a routine maintenance schedule, you can prevent unexpected breakdowns and extend the service life of your A10V pump.

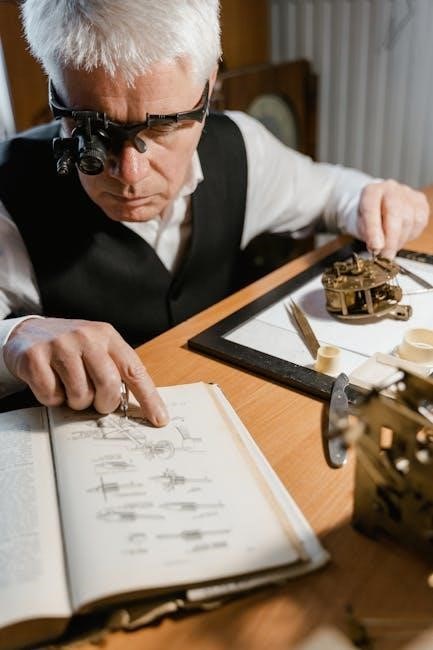

6.2 Repair Procedures

Repairing an A10V hydraulic pump requires careful disassembly and inspection of internal components. Begin by removing the pump from the system and disassembling it to access the rotary group, pistons, and port plates. Inspect each part for wear, scoring, or corrosion, and replace any damaged components using authorized parts. Clean all surfaces thoroughly to ensure proper reassembly. When reassembling, align the components precisely and tighten bolts to the specified torque values to avoid misalignment or leakage. After reassembly, perform a pressure test to verify functionality and check for leaks. Regularly refer to the manufacturer’s repair manual for detailed instructions and safety precautions. Proper repair procedures ensure the pump operates efficiently and maintains its longevity, preventing premature failure and reducing downtime.

6.3 Troubleshooting Common Issues

Troubleshooting common issues with A10V hydraulic pumps involves identifying symptoms and addressing root causes. Low flow rate may indicate worn pistons, blocked port plates, or incorrect swashplate alignment. Noise during operation could stem from misaligned rotary groups, loose retaining balls, or insufficient lubrication. Leaks often result from damaged seals or improper connections. Refer to the parts PDF for exploded diagrams to locate affected components. Start by inspecting the pump’s internal parts, such as the pistons, barrels, and rotary group, for signs of wear or damage. Replace faulty components with genuine or remanufactured parts to ensure compatibility and performance. Always follow the manufacturer’s repair manual for step-by-step guidance. Regular maintenance and timely repairs can prevent costly downtime and extend the pump’s service life; Proper troubleshooting ensures optimal functionality and minimizes the risk of further damage to the hydraulic system.